Paper pulp packaging is now a core target for firms around the globe since they shift from unsustainable components toward eco-pleasant methods. Molded pulp packaging offers a sustainable and cost-successful way to make higher-excellent packaging which is customizable and biodegradable. 1 place driving innovation pulp molding machine manufacturers will be the introduction of significant-effectiveness pulp molding device, such as the Dwellpac Semi-Hotpress equipment. These machines assist companies streamline creation while making sure precision and reliability.This information will explore The true secret characteristics of large-efficiency pulp molding machines, servicing techniques for very long-expression use, approaches to chop expenses while maximizing output, And just how automation boosts output and high quality. no matter if you might be a business owner or a packaging Skilled, you can expect to obtain precious insights to aid optimize your generation method.

Table of contents:

essential Features of large-Efficiency Pulp Molding devices

servicing Tips for extensive-Term Machine efficiency

Charge-conserving Strategies in creation

How Automation increases Output and good quality

Key capabilities of higher-performance Pulp Molding Machines

higher-efficiency pulp molding devices are revolutionizing how molded pulp makers run. The Dwellpac Semi-Hotpress device is one particular this sort of example. It stands out for its State-of-the-art control method, superior clamping precision, and seamless hydraulic performance. With capabilities like precision shaping and eco-welcoming mold urgent engineering, it makes certain that each individual eco-pleasant box packaging products is constant in top quality and toughness. This is vital for industries needing customized answers like food packaging, electronics, and industrial parts. these kinds of machines also support An array of custom molded pulp packaging needs, giving important flexibility in manufacturing.

servicing Tips for prolonged-Term equipment general performance

Maintaining a pulp molding equipment is significant to making sure dependable output and maximizing its lifespan. frequent routine maintenance responsibilities involve cleansing the molding surfaces, inspecting hydraulic systems for use and tear, and ensuring the control technique is up-to-date for peak efficiency. The Dwellpac equipment is designed to simplify these processes, enabling molded pulp companies to streamline repairs. typical inspections and proactive care not simply reduce unanticipated breakdowns but will also enable manage the precision requirements necessary for substantial-good quality paper pulp packaging.

Price-Saving Strategies in generation

Expense-effectiveness is a first-rate concern for molded pulp producers. To save charges though protecting good quality, they could enhance materials usage by leveraging effective pulp mildew pressing technological know-how to attenuate waste, put money into energy-efficient machinery just like the Dwellpac Semi-Hotpress equipment to reduce Electrical power consumption, and teach staff members to totally employ Innovative equipment in order to avoid glitches that bring on inconsistencies or wastage. Furthermore, purchasing eco-friendly components in bulk may also help reap the benefits of lower charges and minimize All round creation expenses. By adopting these methods, producers can stay aggressive although offering significant-high-quality, custom made eco-friendly packaging to clients.

How Automation Improves Output and top quality

Automation happens to be a pivotal aspect of contemporary generation processes. Sophisticated pulp molding machine suppliers, like Dwellpac, combine automation to enhance operational performance. Automated programs, by such as features like intuitive Regulate panels and true-time precision checking, reduce the probability of human faults. This ensures that each mold produced satisfies rigorous good quality benchmarks. With automation, enterprises may also tackle substantial-scale production runs more competently, Conference specific deadlines though developing molded fiber packaging at competitive rates. In addition, the regular high quality accomplished via automation reinforces purchaser belief in eco-pleasant packaging alternatives.

superior-effectiveness pulp molding machines are enabling companies to meet escalating demand for sustainable packaging methods. By purchasing Superior technologies, firms can develop tailor-made molded paper pulp items that not only safeguard the atmosphere but also present excellent performance and toughness. With impressive devices and considerate maintenance practices, enterprises can triumph over production worries, lower operational expenditures, and offer eco-friendly products which cater to world sustainability goals.

Edward Furlong Then & Now!

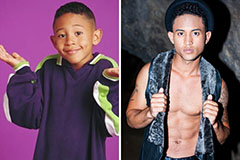

Edward Furlong Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!